URBAN PUMP SERIES (EP 04) - Multi Stage Pumps, Pumping In Series & Parallel

Urban Pump Series

Part 1 - Getting Water

Episode 4 - MUlti stage pumps, Pumping in series & Parallel

First, The Basics

Before we jump into the fundamentals of Dual Stage Pumps and pumping in Pressure or Volume (aka Series or Parallel), I want to ensure we hit on a couple of basic concepts.

First, the two most important concepts that every Driver Engineer needs to understand as it relates to pumping and aggressive, interior firefighting:

Sufficient VOLUME (measured in gallons per minute, GPM) is necessary to extinguish a fire, and

VELOCITY, or sufficient speed to reach/penetrate the desired target.

Remember that "sufficient volume" is relative to the fire in front of us. Typically, a small fire will require lower volumes of water. In contrast, larger fires will require significantly greater gallons per minute to extinguish. Our’s is a game of matching GPM to BTU on the fire ground!

When discussing "velocity," things can become a little tricky. This is because the last time I checked, we don't have a "feet per second" gauge on our pump panels. Instead, we measure a byproduct of the velocity being imparted to the water by our centrifugal pumps... pressure (psi).

Hear me out...

As water enters our engine through the intake manifold (which we discussed in a previous episode), it is introduced via the eye of the pump. This eye at the center of the impeller rotates at speeds of up to 2,000 RPM. The faster the impeller turns, the greater the velocity imparted to the water. This is then captured as pressure by confining it within the impeller’s casing (and the greater pump/hose system). This is where the second measurement (psi - pounds per square inch) that we utilize in the modern fire service comes from. And although psi is NOT technically a measurement of velocity, it's the closest thing we have to express the force that moves water in our system - which is a critical component to the function of firefighting.

Without sufficient volume (GPM), the fire can't be extinguished.

Without velocity and sufficient pressure, we can't reach/penetrate the fuel source to properly extinguish a fire.

Our engine's pump allows us to maximize both of these. Further, if you are fortunate enough to run on a dual-stage pump, you now have a force multiplier on the fire ground that allows your pump to be set up to maximize these to a greater extent.

Pumping In Pressure / Series

The first mode we will look at is our pump running in series. We also call this "pumping in Pressure."

When our two-stage pump runs in Series, we have routed water so that the two impellers have been set up in a "series" or “stacked.” The goal here is to maximize the pressure capacity/output of our engines.

As water enters the intake side of our pump, it is routed (via the transfer valve and two flapper valves that close) from one impeller into the eye of the second impeller. As velocity is imparted to the water by our first impeller, it is discharged and routed directly into the second impeller (the stacking effect we mentioned above). The second impeller does its job to increase the incoming pressure even further (via imparted velocity that is then contained by the pump casing) and is now ready to be discharged to the fire ground.

As a FORCE MULTIPLIER, Series allows us to take the already pressurized water source (the municipal water system via hydrant) and add TWO levels of pressure increase to the total discharged volume. This is how we achieve our goal of maximizing pressure capacity, which is directly tied to how fast we can move water through our pumps, hose, and nozzles... which is one of the two key elements of hydraulics/pumping.

A Simple Scenario...

These numbers are completely fictitious but serve as round numbers that can help us better understand this PRESSURE/SERIES concept:

We have a 50psi hydrant feeding our engine via a 5" supply hose.

If impeller #1 produces 500 GPM @ 100 psi, it will take the incoming hydrant pressure and increase it to 150psi.

Then impeller #2 will increases the original 500 GPM by another 100 psi...

Combined, our dual-stage pump is able to produce 500 GPM @ 250 psi (50+100+100=250psi)

Watch The Video…

Pumping In Volume / Parallel

The second mode we will look at is our pump running in parallel.

When our two-stage pump is running in parallel, the two impellers are now “running together,” “next to one another,” or “side by side.” In Pressure mode, our impellers were stacked... now, they are split. Now, the physical properties of our pump haven't changed in terms of "stacking" or "splitting" our impellers. Rather, we accomplish this by routing water via a simple clapper valve.

As water enters the intake side of our pumps, it is split/routed into two pipes, feeding both impellers simultaneously. Both impellers rotate at the same RPM (because they are on the same drive shaft) and produce the same volume (GPM) at a given RPM which ultimately increases in volume since both impellers are discharging their capacity.

If this is confusing, let’s go back to our simple scenario and see if this helps.

Back To Our Simple Scenario...

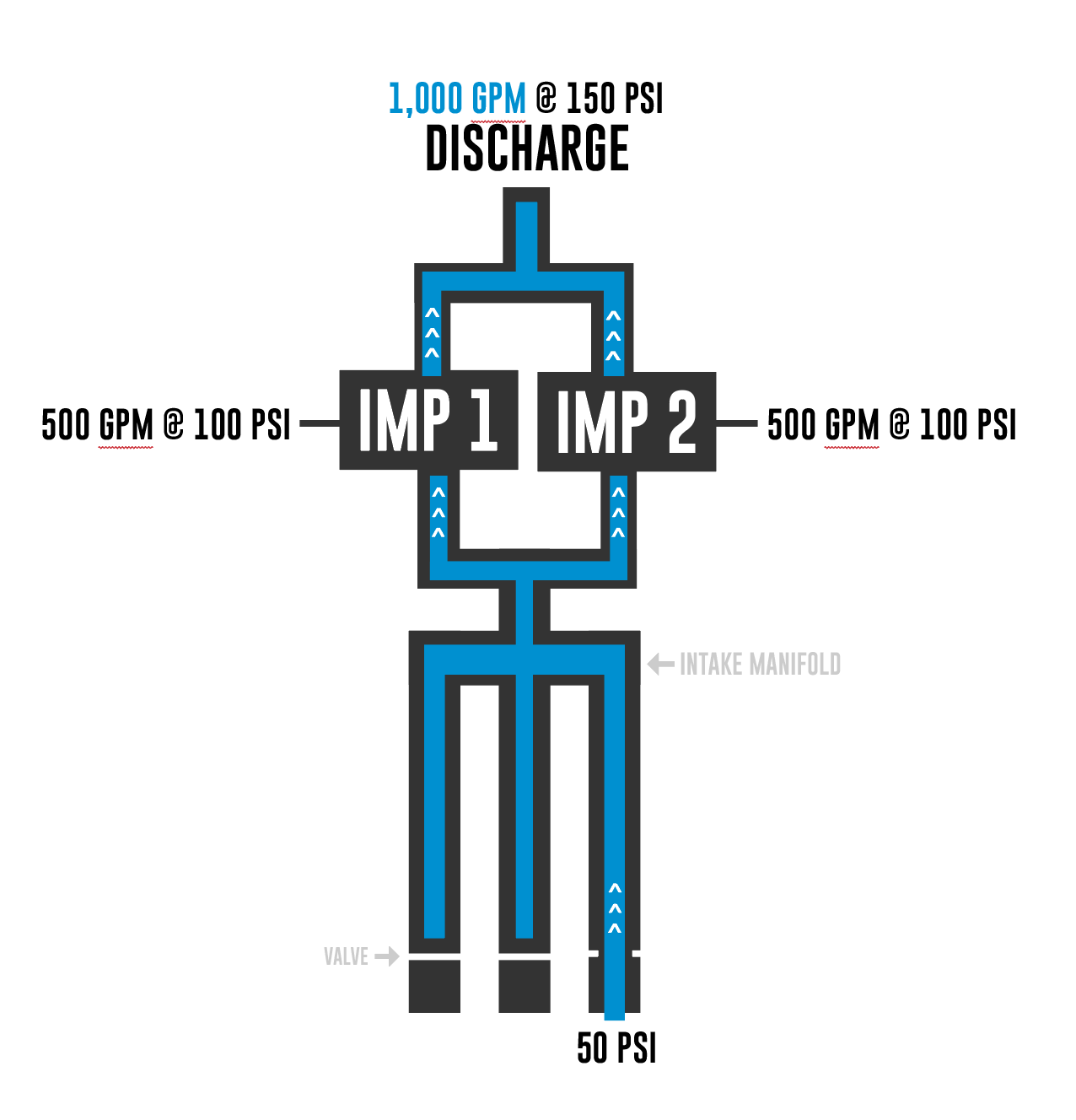

We have the same 50psi hydrant feeding our engine via a 5" supply hose.

If impeller #1 produces 500 @ 100 psi...

Then impeller #2 produces 500 GPM @ 100 psi as well...

Combined they will produce 1,000 GPM @ 150 psi (50 + 100 = 150)

WATCH THE VIDEO…

When & How To Transition

One of the first questions that typically arises is, "When do you transition from Pressure to Volume mode?

Here is what the book (Pumping Apparatus Driver/Operator Handbook, IFSTA) says...

"If the pump is a multistage, set the transfer valve to the proper position before pressure builds in the pump. In most cases, the pump should be in a SERIES (PRESSURE) position if the operation is from the tank because maximum flow is limited by the size of the pump piping. If it appears that the pump will be required to furnish more than 50 percent of its rated capacity, it should be set to the PARALLEL (VOLUME) position from the start. Some pump manufactures may recommend that their pumps be in the SERIES position until up to 70 percent of capacity is required." (p. 247)

This is pretty much spot on in my opinon. From my experience, once our engines hit half the rated capacity of our pump, it becomes essential to make the transition if we are to run the pump efficiently and maximize our volume capacity.

What isn't readily clear is what the rated capacity of our pump is in the urban environment. This is because once we connect to a pressurized water source (the municipal hydrant system), the capacity of our pumps will be significantly higher than the data given on the placard on our pump panel:

Since we've already addressed this concept in a previous episode, I encourage you to check it out if you're joining us for the first time on this episode. You can view it here - https://therollsteady.squarespace.com/training/urbanpumpseries1

The key thing to remember is that an individual hydrant’s capacity depends on the available volume AND the speed with which that volume is discharged from the hydrant. This means that every single hydrant will be slightly different concerning its volume capacity.

With this in mind, I've developed a couple of basic rules of thumb (aka models) that I work from and teach here in the City of Dallas. IMPORTANT - you will need to conduct several training evolutions to test and/or develop your version of these models.

Most hydrants in Dallas can easily supply upwards of 2,500 GPM. Thus, half the rated capacity would be ~ 1,250 GPM. Once our target flow from multiple lines approaches this number, I would make the transition.

If I am going to flow to a ladder pipe, I will automatically start in VOLUME mode simply because most of our trucks target a minimum of 1,200 GPM.

If I am planning to flow my deck gun with a 2" SB tip (defensive operations), I will automatically start in VOLUME mode because my target flows will be ~1,200 GPM.

Look, Listen, Feel...

Since a hydrant's performance is based on several factors, having a theoretical number ("half the rated capacity") for when we should transition from PRESSURE to VOLUME can be somewhat limiting. Rather than just relying on a set number, I try to push younger members to develop a more "in tune" approach to this concept. This can serve us well when our hydrants are underperforming (lowering our total capacity), and even more when the heat of the battle has caused a bit of tunnel vision and we haven't been tracking our target flows. This is where we can build in (through consistent training) some basic feedback mechanisms that will cue us that we need to consider this transition.

A really powerful training evolution that we've done with several members here in Dallas connecting to a yellow top hydrant and pumping 1,200 GPM to one of our truck's ladder pipe in PRESSURE mode.

We move slowly toward our target flow, paying close attention to what we see on our intake and discharge gauges, along with monitoring our RPM. We also are hyper-focused on what we hear - how does the engine sound? Does it sound like the engine is working efficiently? Or does it sound like we are taxing the hell out of it? Most likely, you'll see and hear that you're closing in on the governed speed of your apparatus.

Lastly, we take note of what we feel. I prefer to connect my supply hose to the panel side. I know there are many safety-conscious people out there who will disagree with this, but it gives me an extremely tangible feedback mechanism that makes you a better operator. Plus, there are ways to mitigate the safety issue if that concerns you.

Chances are, you'll feel a noticeable "shake" in your supply line as you close in on that "half the rated capacity" point. We're losing pump efficiency, which is confirmed by three very tangible feedback mechanisms - what we see, hear and feel.

After we've confirmed our flow rate with the truck operator, we idle down and transition the pump to VOLUME. We repeat the same evolution and compare again what we see (less RPM), hear (less engine noise), and feel (less shake and smoother action from our pumps). Every time, there is this "aha!" moment in which the theory becomes a reality, and the pump operator sees how this transition between PRESSURE and VOLUME should function and what is looks/sounds/feels like if we don’t. It also reinforces that most of our hydrants in Dallas can supply 2,000-2,500 GPM and allows them to develop these general rules of thumb before their next big fire.

BONUS... Dealing With A "Hot Plug"

As we've started transitioning to our new hose and nozzle package here in Dallas, a question that has been asked a lot is, "How do you deal with a hot plug?" Is the answer to simply gate the line down enough?

Although this isn't something, we would normally talk about when discussing PRESSURE and VOLUME modes on a dual-stage pump, leveraging one of these modes is a way to deal with lower PDP when we have a hot hydrant.

Check it out...

For those interested in our new TRU-ID hose and Elkhart Nozzles you can check out the following resources:

YouTube Series - https://youtube.com/playlist?list=PLV5UfqoDi7nPjn2IE753jSS1zN14Zs2v2

Roll Steady Network Article (with the videos) - https://therollsteady.squarespace.com/training/newhoseandnozzle

Conclusion

Multi-stage pumps are a force multiplier on the fire ground. It boils down to pump efficiency and producing the necessary volume and velocity to accomplish the mission. There is a time to pump in PRESSURE and VOLUME, the key is knowing when each is appropriate. There isn't a way for me to outline all situations where each would be appropriate/inappropriate, so I encourage you to take the information you've gathered here and converse with the more senior members at your fire station. Ask them for specific situations where each applies. Trust me, you'll learn 1000X more through their experience and testing it on the training ground than you will by just reading this article.

Until the next episode, hold fast and continue to raise the bar!

DISCLAIMER: Dallas Fire-Rescue does not endorse or necessarily promote these videos. The information herein is my best understanding of the material covered and the subsequent views expressed are my own and not necessarily those DFR. These videos are strictly for educational purposes only. It is critical that you follow your department's MOP/SOP, and talk with your Station Officer (and crew) before implementing anything you see here on The Roll Steady.

© 2021 The Roll Steady, LLC. All Rights Reserved.